Skin on Frame Boatbuilding: An Overview

A lot of potential would-be boat builders ask us, "What’s the best boat for a beginner to build?” There are a lot of ways to answer that, and I’d argue that the #1 factor is, “What boat would you get the most enjoyment out of owning?” But setting that key consideration aside for a moment, a skin-on-frame boat is a good first project for the aspiring boat builder who wants a relatively quick, attainable project. These boats come together pretty quickly, so you can get out on the water and start enjoying the fruits of your labor.

Read on to see what goes into building your first skin-on-frame canoe or kayak, and what makes this such a great method for new boatbuilders.

What is Skin on Frame boat building?

In broad strokes, the skin-on-frame process involves building a structure made up of frames, longitudinal stringers, and stems at the ends. Those components are tied together, and then you stitch a skin over the frame. That skin is then coated with a finish that makes the surface scratch and tear resistant, and also waterproof.

Essentially, that’s it. If you read further you can get into more of the details, but the general concept is really quite simple.

A traditional construction method for everyday functionality

Skin on frame is arguably my favorite method of boat construction. Why is that? It’s so darn simple. Imagine that you lived in the Aleutian Islands centuries ago. The materials you had available to you were sourced from the beach, and from the animals that you hunted. Material perfection wasn’t the goal, function was. That’s something that hasn’t changed. Even as centuries passed and modern materials evolved, functionality remains at the core of skin-on-frame design.

Nuts and bolts, or rather knots and twine

Depending on the plans you are building from, you are likely to have limited or zero metal fasteners in your completed boat. Traditionally, all of these parts would have been tied together with various bits of animal or even stringy plant fibers. Modern skin on frame boat builders use nylon upholstery thread and artificial sinew. Many skin on frame builds also include dowels and glue to help hold wood bits together.

Basics of the frame

A Skin on Frame boat has frames at regular intervals. These can be marine plywood, laminated wood, steam bent wood, limber branches, driftwood etc. These frames don’t actually make contact with the skin, but their shape is important. Part of the beauty of skin on frame boat building is that it is a very forgiving building method. Getting the frames reasonably close to the “right” shape is usually good enough.

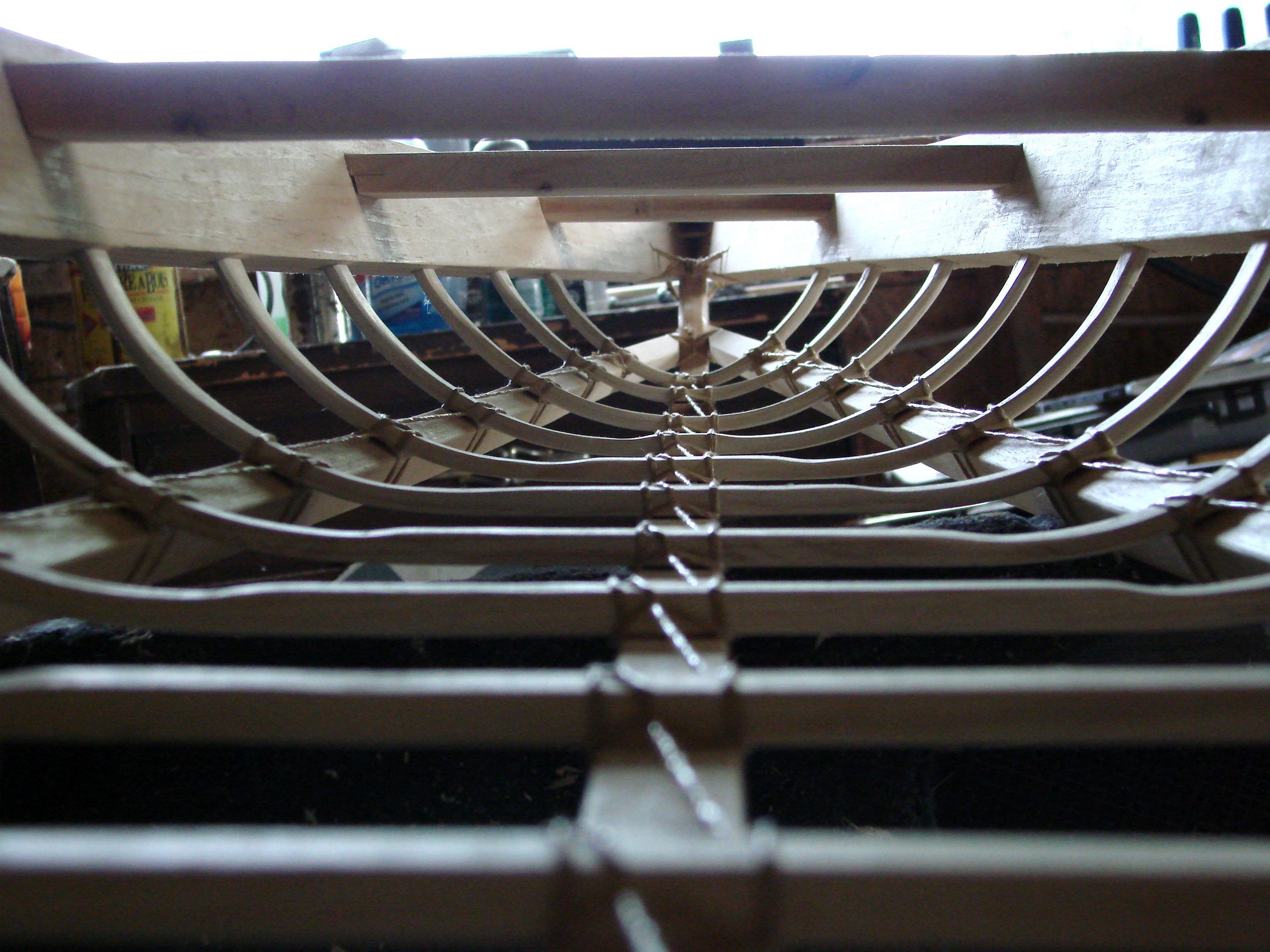

A closer look at the frame: notice the knots, lashings and steam bent frames.

Longitudinal stringers are the structural components that actually make contact with the skin, and these are stiffer than the frames. When you tie the longitudinals and frames together, the frames will pull to the longitudinals, effectively fairing the shape. They all kind of find a happy balance. These longitudinal components are usually made up of a keel (right down the middle of the boat), multiple stringers as you move up around the shape of the hull, one at the sheer, and one right down the middle of the deck (in the case of a kayak). Add in a stem and stern post to tie both ends together and you're all set, more or less.

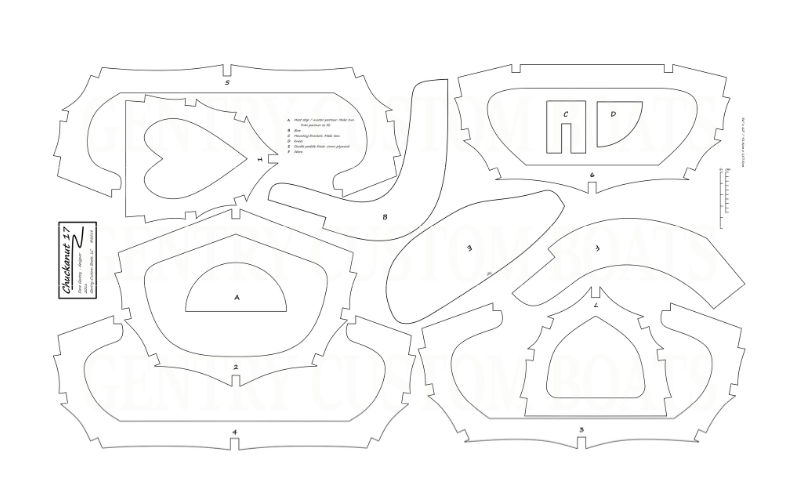

An example of what to expect in a set of frame plans: the Chuckanut 17 is designed by Dave Gentry

Skin

I’m pretty sure that I was the butt of a joke several years ago when a First Nations gentleman from NE Canada told me, through an interpreter, that his people have switched over to using ballistic nylon for their skin on frame watercraft. “Walrus isn’t what it used to be,” he said. (Maybe it wasn’t a joke, I don’t know.) Regardless, most folks nowadays will skin their boats with either ballistic nylon or polyester fabrics.

The weight of the skin that you choose has a lot to do with the size of boat you’re building, as well as the expected wear you might anticipate your boat will see. Lighter weight equals less wear resistance, but it’s easier to carry. Heavier weight would be longer wearing, but more of a load to haul. Once the skin is all sewn up you actually shrink it just a bit– don’t worry, this is a really simple step. That is like a straight jacket for the boat, squeezing everything tight and really helping to stiffen the hull up.

Coating

Commonly, folks will choose to apply a dye to their skin prior to applying the finish. This is very much a personal preference sort of choice. Some folks like the raw fabric coated with the two-part polyurethane. Others prefer a warmer tone all the way through, browns and reds. You have options on color. The finish you apply, however, is pretty agreed upon to be 3-4 coats of a two part polyurethane. Once cured, the polyurethane treated nylon makes a waterproof and tough skin. This finish remains flexible which is necessary for a skin on frame boat. The finish is applied by hand with a roller or brush, no special skills or tools are necessary.

Durability

I saved this aspect for last because it’s commonly the first thing on someone’s mind when they're considering a skin on frame boat build. The fear is that every nudge from a rock, stick, barnacle or fish-hook will immediately result in a slash right through the thin skin. Like Douglas Fairbanks sliding down the big sail on his rapier in Black Pirate (1926).

Douglas Fairbanks, Black Pirate (1926)

The much more realistic and common threat is abrasion from running up on a beach or rubbing along rocks. Polyurethane coated nylon excels for this purpose. The coating is quite durable on its own and will act as a tough sacrificial surface, taking the brunt of most scrapes.

If the abrasion incident is significant enough to get through the coating, the nylon is quite strong, and difficult to cut when coated. In the unlikely event that you do get a puncture in your hull, you can sew in a patch and recoat. Or you can re-skin, which is common every 5-10 years, depending on your use.

Example of damage made by rebar, taken from Cape Falcon Kayak on YouTube. Watch the full video for more on durability here.

A few reasons why skin on frame boat building is an excellent choice for a first time builder:

- You can build one with limited shop tools. A full shop is not really a requirement.

- The nature of the method is quite forgiving. You don’t have to be a total perfectionist to get a workable shape.

- It’s easy to correct your work as you go. Because the bits and pieces are all tied together, you can easily remove and replace a part that didn’t work out quite right, during the build.

Generally skin on frame boats are smaller designs (although there certainly are exceptions) and they are very light weight. Throw in that they require low maintenance efforts and cost from you, and they look really cool. Everyone loves the regular and repeated look of steam bent frames in a lapstrake boat… yet with a skin on frame boat, you can see them from the outside of the boat too. Doubly cool.

Ready to give it a shot? Check out some of our most popular skin on frame boat plans below!

The Great Wicomico

Recent Posts

-

Bestselling Boat Plan Designers of 2024

Fun fact: In 2024, you all collectively purchased over 2,500 boat plans from Duckworks! (That's 20 …Jan 25th 2025 -

A New Chapter in Duckworks History

Hi everyone, Katie here to give you an update on what's happening behind the scenes here at Duckwork …Sep 24th 2024 -

Designer Spotlight: Frank Smoot

How I went from not knowing squat about boats (or sailing) -- to designing a little trimaran I can’ …Aug 28th 2024