The ins and outs of this popular buillding method

Strip planking is an increasingly popular method of boat construction (over half of all our new design work is for strip planked craft). It enables the amateur boat builder to produce a beautiful round bilged hull without having traditional boat building skills. It is certainly an easy method of round bilged hull construction and one which produces a very tough 'one piece' monocoque hull shell which will require little maintenance and which will last far longer than a conventionally built wood hull.

This new version of the Manual starts by discussing the merits of strip planking and the types of hulls that are best suited to this method of construction. It goes through the possible difficulties of strip planking certain hull shapes and how these difficulties may be over come. Suitable materials for constructing the hull are discussed including the use of square edged versus profile edged planks and epoxy versus polyurethane glues. Guidance and examples are also given for calculating material requirements.

Different types of building jig are discussed along with the marking, shaping and the setting up of moulds. The setting up of the internal backbone structure is then covered and after a description of the planking process, the Manual covers the best methods for preparing the hull for finishing. Veneering and glass sheathing are then described. Finally, tool requirements and the care and repair of strip planked hulls is described.

Note - Deck and coach house construction are now included. The Manual of Fit-Out for Yachts and Launches will be an excellent companion to this manual and will help you complete your boat.

Sample Pages

Contents

Introduction

The Internal Structure of a Modern Strip Planked Hull

Chapter 1

General Discussion About Strip Planking

1.1 General

1.2 Problems Associated with Strip Planking

1.3 What Hull Shapes can be Used?

1.4 Possible Changes to the Hull design

Chapter 2

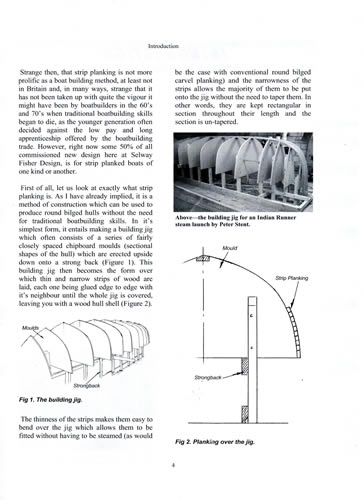

The Building Jig

2.1 General

2.2 The Building Jig

2.3 The Strong Back

2.4 The Moulds

2.5 Mould Spacing

2.6 Setting Up the Moulds

Chapter 3

Internal Hull Structure

3.1 General

3.2 Internal Stem/Stern Post

3.3 Transom

3.4 Hog (Internal Keel)

3.5 Floors & Frames

Chapter 4

Materials for Strip Planking

4.1 The Planking

4.1.1 Square Edged

4.1.2 Cove/Convex (Bead and Cove)

4.1.3 Tongue and Groove (Speed Strip/Fast Strip)

4.2 The Species of Wood Used

4.3 Glues

4.4 Fastenings

4.5 Sheathing

4.6 Materials Quantities

4.6.1 Planking (incl. glue)

4.6.2 Glass Sheathing

Chapter 5

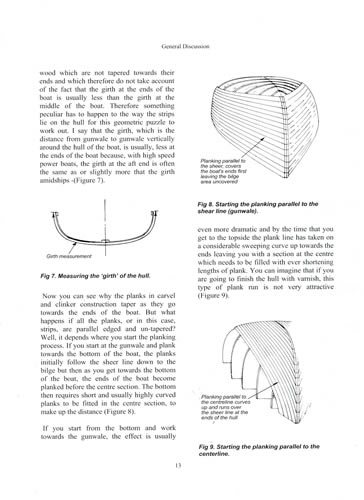

The Planking Process

5.1 Preparing the Jig

5.2 The Lay of the Planking (also refer to Chapter 1)

5.3 Joining the Plank Lengths

5.4 Planking

Chapter 6

Finishing the Hull

6.1 Cleaning Up the Hull

6.2 Glass Sheathing the Hull

6.3 Veneering the Hull

6.4 The Interior of the Hull

6.5 Internal Structure

Chapter 7

The Hull Exterior

7.1 Fitting Gunwales, Rubbers etc

7.2 Skeg, Deadwood and Wood Keels

7.2.1 Fitting Skegs/Deadwood

7.3 The Outer Stem

7.4 Bilge Runners

Chapter 8

Deck Superstructure

8.1 Decking

8.1.1 The Deck Structure

8.1.2 The Cockpit

8.1.3 The Deck

8.1.3.1 Sheathed Deck Covering

8.1.3.2 Teak Deck Covering

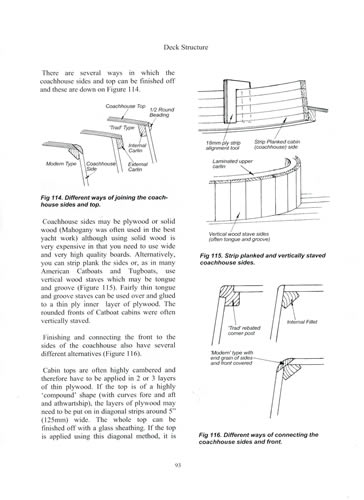

8.2 Coachhouses, Cabin Tops and Superstructures

Chapter 9

The Care & Repair of Strip Planked Hulls