This hull design will be the first of a series of power boats aimed at fishermen who want a bigger hull than the one's I've produced before. I also call them something without “lake” in the name. Most people are out boating and fishing on man made reservoirs and not on naturally formed lakes. It wasn't until later in my life, that I found out that Kansas were I grew up, has no natural lakes. Many of them have “lake” in their names, but all have a dam somewhere along their shoreline. So this line of designs will be called Reservoir's, and will be made from a pair of 4x8's scarfed together.

|

|

This version of Reservoir uses two 9mm/3/8” thick 4x8's to make up the hull. I've gone to the thicker 9mm/3/8” plywood to give the hull panels a bit more stiffness as this heavier hull powers through wave sets. It's also a wide hull for it's length, and I wanted that for stability while stopped for fishing, and to carry more load in passenger weight, and the weight of an outboard motor up to 40hp. The name for the hull comes from it's finished length after the hull panels are assembled. Using 9mm/3/8” plywood, you will have a 4 1/2” overlap at the scarf for a 12:1 ratio; so the “panel set” is 187 1/2” in length. The hull is them 15ft 3” long, with a 66” beam, measured at the outer edges of the plywood, and not the outer edges of the rails you will add.

I haven't calculated any approximate weights yet, but 9mm/3/8” plywood runs from 28 lbs per sheet for Okoume A/B BS1088 Lloyds approved, 33 lbs for standard fir, and 38 lbs for Merranti A/B BS1088. The Okoume and Merranti can have either 5 or 7 layers per sheet; the fir will probably have 5. I will figure out how many more sheets it may take for final assembly this hull and “estimate” how much epoxy, tape, and glass cloth will be added for a final hull weight. I'm thinking it will be in the 400-500's.

|

|

The hull is “tall sided” for a drier ride in the waves that big reservoir's can generate when the winds pick up during fast moving storm fronts. With this in mind, I've made the transom height 22”, so you will need to use a “long shaft” outboard, or cut down the transom height to fit a shorter motor. If you do, you will need/should add another full height bulkhead ahead of the motor to keep following seas from rolling over the stern and swamping the hull. Also to keep from getting “pooped” if you come into the dock or beach too fast, and the stern wave swamps the hull. I saw this one day as someone came into a crowded dock way too fast. I smiled and quickly walked away, as his boat sank to the bottom.

I will not be doing a prototype of this hull, but I will have several drawings of possible interiors that can be fitted to the hull. You will probably have your own idea of the boat that you want, so I will caution you to keep the “hulls balance” in mind as you build. Once you have the main panels of the hull put together with epoxy and tape, you should find the “balance point” of the hull at that point. When you start adding the panels for your hull, you will want to counter any weight in one end, with a corresponding counter balance of wood in the other end.

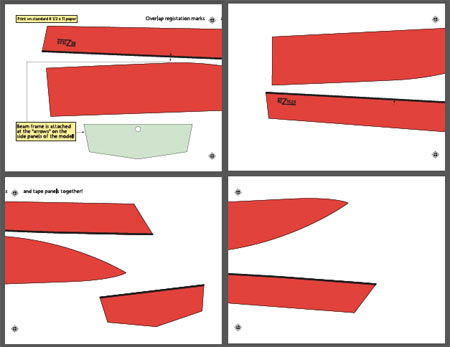

Enjoy putting the PDF model together that is linked below. An earlier version of this hull was tank tested in this YouTube video I made. The hull is a bit wider now than it was for that video.

Thanks Again

Warren Messer

Red Barn Boats

click the image above for a free PDF

file to print and build a model from