This design won an Outstanding Innovation Award at the Wooden Boat Show 2007.

Click for Professional Boatbuilder article (PDf)

Plywood Stitch & Glue Sailing Skiff

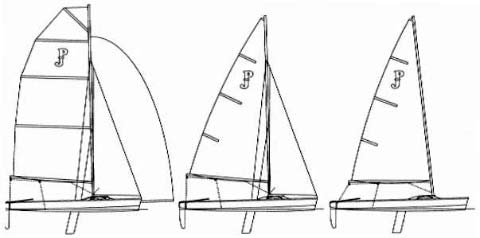

Paper Jet rigs - Turbo, Standard and Lite

Our newest dinghy design, modern performance skiff concept with some traditional touches.

Grow your sailing skills without changing boats - 3 rigs in 1 boat.

~ Paper Jet Lite - Free-standing unirig

~ Paper Jet Standard - Add standing rigging, jib & trapeze

~ Paper jet Turbo - Longer topmast, larger mainsail, add bowsprit & asymmetrical spinnaker - a powered-up performance skiff

Wet deck - open transom for fast draining

Stitch & glue plywood - within the abilities of reasonably skilled amateurs

Built over lightweight interlocking ladder-frame - strong & light

Simple hardware layout - great training boat

Traditional rigging features - reduced hardware and cost

The Paper Jet is designed primarily as a performance training boat, with the intention that it can cater for a wide range of sailing skills. I wanted a boat that will allow a club to race it as a class boat that will give exciting sailing to those who have the skills but will also allow less experienced sailors to develop their sailing skills in the same boat at a much lower level of performance. It is not suited for learning the most basic sailing principles single-handed. We recommend double-handed training until the student has enough expertise to sail single-handed. For single-handed training first learn the basics on a Sunfish or similar boat then move to the more performance oriented Paper Jet.

The same features that I designed into it for club use will allow a family to use one hull as the platform on which Dad can have his excitement of blasting across large expanses of water but junior can sail the same boat (if he can pry it loose from Dad's grip) with a smaller rig and at slower speed.

I did not try to produce a design that will sail the pants off any of the other skiffs or single-handers. It is fast and it is exciting to sail with the Turbo rig, but from the outset (this boat was in the back of my head for over 10 years) it was intended to provide an economical path for sailors to progress between boats like the Optimist and the costly single-handed skiffs without having to trade up their boat each time to go the next step. They can build a Paper Jet at the cheapest level or the level that they think that they can handle and progress from there. Meanwhile, as long as Dad is not out sailing, the kids can use the same boat at a more basic level. It makes sailing more viable for many families. With time and skill improvements they can move into more costly boats if they feel the need.

Standard rig in light conditions.

This versatility is achieved by making some of the components modular. The wooden mast has two interchangeable topmasts and two mainsails of very different sizes. These items, along with a jib, asymmetrical spinnaker and retractable bowsprit, are used in different combinations to give the different rigs. The mast is supported at gunwale level by an X-shaped brace that distributes the loads, stiffens the hull and gives two mast positions. The forward one is used for the Lite rig and the aft one for the other two rigs.

Much of the rigging uses details borrowed from gaff rigs, using lashings and soft eyes instead of stainless steel hardware. These tie the standing and running rigging to the hull and boom with greater strength than thru-bolting stainless straps to the wooden structure, also reducing cost and weight.

The mast, boom and bowsprit are hollow timber, constructed by the birdsmouth method but modified to produce a very attractive striped appearance. This is achieved with alternating strips of cedar (for lightness) and poplar (for strength and stiffness). The sail track is a length of plastic pipe that is split along one edge and epoxied to the mast and faired in at the sides or an awning track can be used. The topmast is sleaved to the mast just above the hounds. This allows a quick change between the standard and Turbo rigs because everything from the hounds downward remains unchanged when the topmast is changed.

For those wanting an easier rig to build, the wooden mast can be replaced by a round aluminium tube with riveted track. It will not be as pretty but will require less skill to make. If it is to have the buoyant characteristics of the wooden mast then the aluminum tube must be sealed both ends and at all rivets and rigged with external halyards. If you do not do this, expect recovery from a capsize to be more difficult. With the wooden mast she floats on her side and waits while lines are uncleated etc for righting and the immersed wing prevents her from blowing away downwind. With righting lines rigged under each wing, she is easy to right.

Free-standing Lite rig

Hull construction is stitch & glue plywood with a difference. The entire boat is built from 4mm plywood, so it is very light and needs more internal support than is normal with thicker plywood. I did this by fabricating a full-length plywood ladder-frame backbone that has interlocking transverse plywood frames. This necessitated securing the framework to building stocks for rigidity until the hull skin was complete.

After completing the hull skin, it can be released from the building stocks for the remainder of the work. The stocks continue to serve as a support for working on the boat either right way up or upside down, depending on the work that is being done. This keeps it at a convenient and comfortable working height.

The detailing that I worked into this design is simple but it gives loads of opportunity for showing off your woodworking and finishing skills. I used cedar for lightness along gunwales and for the wing leading edges but capped them with poplar to give a nice contrast while adding strength and stiffness to the structure. The result is a very light boat (hull/deck weight less than 100lb) that is also very stiff.

The hull shape is hard chine, with a V-bottom that twists from vertical at the bow to almost horizontal at the transom. The wings are intentionally low and horizontal so that the leeward rail will immerse if the boat is over-powered in gusts, adding buoyancy to leeward to help her recover. The wings have airfoil shaped leading edges to generate lift, also to help her to recover. Most skiffs have wings that can trip the boat if immersed, causing a capsize. These wings are designed to cancel out that tendency and also serve as additional planing surfaces.

Two Paper Jet 14s nested for travel.

The standard plan package comprises 16 fully detailed drawings, full size paper patterns of all of the plywood components and how to set them out on the plywood sheets, as well as a 50 page manual with 200 photos and step-by-step instructions.

This boat will give fun sailing to one person in the Lite format and two teenagers or a lightweight couple with the Standard rig. It is a trainer, so the deck layout was kept simple and fairly basic. A self-tacking jib was intentionally left out of the concept so that there is something for the jibhand to do in sailing the boat. It also gives high-performance sailing to those who want to take it to the next level. It does so without resorting to hi-tech building methods that are beyond the ability of most home builders.

We exhibited the Paper Jet at the Wooden Boat Show at Mystic Seaport In June/July 2007. In the Concourse de Elegance the judges awarded her an "Outstanding Innovation" award for the combination of features included in her design.

Although intended as a training boat, the Paper Jet is not suited to learning the most basic sailing principles single-handed. We recommend double-handed training until the student has enough expertise to sail single-handed. For single-handed training first learn the basics on a Sunfish or similar boat then move to the more performance oriented Paper Jet.

Scott Murphy was new to sailing and built himself a Paper Jet. After first learning basic sailing on a Sunfish he has progressed to his Paper Jet with the Lite rig and sent the report below on 21st September

2009.

"I am so impressed with the amount of speed you can get out of the una rig. I was out in 9-13 knot winds got her going fast enough to get the out haul lines howling in the wind. Saturday step up a bit to 10-15 knots had lots of fun. Then Sunday it stepped up again 18-22 knots. I had so much fun and learned just how much she will take. I also had my first at speed spill. Had her heeling pretty good heading south on an east wind at a good clip. I knew I was on the edge just needed to push to learn more. A gust came up and put me over.............. Swam around to the rudder regained breath then went around to the center board grabbed the righting line about in line with center board put a knee on the center board and put my hands on the wing and gave a little pull and she came right up. With the main sheet uncleat she waited patiently while I swam back around to the back climbed in over the rudder. Got on the deck and regained full composure sheeted in and off we go.......... Thanks again this is a boat full of fun and I have not even touched the jib!

Bill Of Materials

4mm OKoume Marine plywood

Sheets 1220x2440mm [8'x4'] - 6

Meranti, Douglas fir or white pine framing

12x12mm [1/2x1/2"] (stringers) - 14m [46'], selected for straight grain

16x32mm [5/8"x1 1/4"] (wing edge frame) - 5m [17']

18x32mm [45/64x1 1/4"] (daggerboard casing) - 1m [4']

19x19mm [3/4x3/4"] (daggerboard casing) - 2m [7']

22x32mm [7/8x1 1/4"] (wing beams) - 3m [10']

16x16mm [5/8x5/8"] Triangular (ex 22x22mm [7/8x7/8"] cut diagonally) - 16m [53']

Cedar

10x32mm [3/8x1 1/4"] (gunwale) - 5m [17']

16x82mm [5/8x3 7/32"] (wing leading edge) - 5m [17']

Poplar, mahogany or similar

10x32mm [3/8x1 1/4"] (gunwale capping) - 5m [17']

12x89mm [1/2x3 1/2"] (rudder blade) - 2m [7']

16x40mm [5/8x3 9/16"] (wing edge cappings) - 5m [17']

16x64mm [5/8x2 1/2"](daggerboard) - 5m [17']

19x25mm [3/4x1"] (wing leading edge cappings) - 2m [7']

Glass etc

50mm [2"] glass tape - 1 roll 50m [50yd]

300g/sq.m [9oz/sq.yd] glass cloth 1.25m [50"] wide - 2m [2yd] (sheathing foils) (extra 1m for Turbo bowsprit)

Laminating epoxy & hardener - 10litres [3 gal] total

Plywood Stitch & Glue Sailing Skiff

LOA 4.10m (13' 5")

Beam 1.63m (5' 4")

Draft 0.12/0.8m (5"/2' 8")

Hull weight 45kg (100lb)

Sail Area Standard

10.2sq.m (109sq.ft)

Sail Area Lite

7.2sq.m (77sq.ft)

Sail Area Turbo

13.6sq.m (146sq.ft) upwind

19.6sq.m (210sq.ft) downwind