If you prefer printed plans for Pacific Pelican, click HERE

In lieu of study plans we have this Pelican Sailboat Article Compilation

Much loved by those who have come to appreciate the logic behind the design

The Pacific Pelican is a special creation, much loved by those who have come to appreciate the logic behind her design, not only in use but in building. We are grateful to Captain Bill Short who came along to design the original Pelican (12') in 1959 and later the Great Pelican (16'). It's pleasant to hear Bill say that our Pacific Pelican (14' 7"), after 30 years with the 12' and 16' versions, finally completes a perfect family.

Bill has worked closely with my father, Ed Barlow, and me since 1982 in this joint design effort. After two quarter-scale models, two full size prototypes, and uncounted hours of design meetings, Bill enthusiastically endorses the Pacific Pelican and our making it available to amateur boat builders with our book and comprehensive plans

Dinghy cruising is a low cost way to have fun and adventure on the water and has given me days and weeks of memorable pleasure. Just because a boat is small enough to fit into your garage and has no cabin does not mean it is unsafe to sail across lakes and bays, along the coast, or up rivers. A properly designed sailing dinghy of around 16' can take you places in safety and comfort for thousands of dollars less investment than an l8'-20' trailer sailer with a tiny cabin.

The Pacific Pelican is specifically intended to meet these criteria of safety, comfort, and low cost. She is deeper, has more sorage space, and is more stable than a racing dinghy or yacht tender. Although not a racer, the Pacific Pelican is fast in a breeze of 7-9 knots. The design incorporates the lines of a Banks dory with the oriental sampan bow. If her lines were extended to the dory's extreme ends she'd be about 22' long. The pram bow is safe, it will not dig in and cause a broach capsize when running before 3Okt gusts in 3'-4' seas; we know, we've done this on blustery San Francisco Bay!

At 14' 7" overall (not including the bow sprit) the Pacific Pelican also serves as a deep and dry day sailer for those wanting a boat safe for spouse and children on local outings. Or, leaving the rig behind, the boat makes a great fishing skiff that can be rowed or motored.

But it's when dinghy camping that the Pacific Pelican comes into her own. I designed her to have a huge amount of open floor space for comfortable sleeping. I unroll 3" thick foam pads that are stowed in plastic trash bags under the foredeck and slide them in under the afterdeck where they reach from the transom out onto the cockpit floor. This provides 6' 6" x 4' of very comfortable bed with more sleeping room for children alongside the centerboard trunk. The headroom under the afterdeck is so generous that it's comfortable to sleep with the open end of my sleeping bag totally out of any breeze and overnight dew. My body weight this far aft settles the stern just enough to create a level floor.

If weather threatens I am prepared. By hoisting the furled sail and boom a few feet further up the mast and securing it in place with a topping lift I can have a tent with standing head room! The boat is so stable a 220 lb. adult can walk on the side and fore decks while setting up such a tent. On an anchor the boat swings into the wind reliably so that the rear wall of a tent can be kept open for the view, light, and air. It can be closed off if it's really nasty outside. A 9' x l2' cover makes a 6' x 9' x 6' tent with all that dry storage an extra under the spacious foredeck.

Sailing is easily managed with jib and main reefable from the cockpit. The broad beam and flaring dory sides make her very stable, she is very hard to capsize as the wind spills from her lug rig long before she goes over. The all wood construction and flotation designed in make her unsinkable and self righting and she can be made self bailing if desired. Despite the low center of effort of the lug rig she has good aerodynamics, pointing very high and planing to windward, even with threeadults on board, in a 15-2Okt breeze. The helm is perfectly balanced under full sail and she ghosts nicely in very light air.

The centerboard and rudder both kick up so, combined with her flat dory bottom, Pacific Pelican is easy to beach. Gunkholing with only 5' draft (board up, of course) is easily done. She can go from a fast rough water cruiser to a laid back pleasure barge without any changes other than adjustment of rig and centeboard.

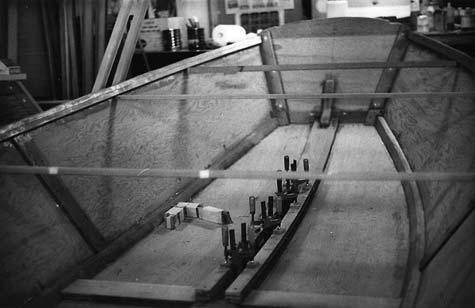

We wanted to make the Pacific Pelican easy to build by the home builder, even one with no previous experience at boat building and with only limited carpentry skills. For a resulting boat that anyone can be proud of for performance and pleased with for accommodation, we decided that a plywood boat of modern monococque construction was the choice. Although building the Pacific Pelican is not a small project, it is very straightforward. You will need about 12' x 20' of shop space with a level floor and room for table saw and workbench.

Complete plans are provided, six sheets which detail the building jig, hull, plywood sheet layouts, and sail/rigging plan. Full size paper patterns are provided for all special shapes like centerboard and rudder. The original 112-page instruction book, a printed and bound workshop book, not copy machine pages, has an additional appendix devoted to details on watertight bulkheads and flotation. We spent a lot of time writing the book, the drawings done by my father, Ed, an engineer, are complemented by many close-up photos. Tool requirements, materials list, shop set-up, and notes on many tricks involved in the building are all included. The book was reviewed by experienced builders for clarity and accuracy. Certainly these must be about the most complete small boat plans available!

How long does it take to build? Obviously this depends on your skill level but we strongly urge you plan on six months and enjoy doing it right for a good boat, not a shabby one, when launching day comes. The time is not required because of difficulty in the building process, there's just a lot of detail involved. We provide patterns for some parts and layouts for all parts to be cut from plywood to reduce waste wood. The method of making full size cardboard patterns before cutting the wood is fully explained. There are no difficult bends to make, no soaking, no steaming. Any necessary curvature is achieved by laminating. No lofting is required, all the curves, bevel angles, and sections have been worked out so that everything fits. No special tools are required, a table saw, hand circular saw, saber saw, and power screwdriver speed up the job, though.

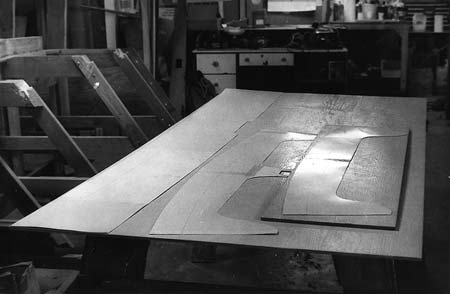

Sample from plans

Materials are marine grade plywood in standard 4' x 8' sheets, straight grain lumberyard fir, and two-part epoxy glue. How much will it cost? About $2,500 to $3,000 (1989 prices - Ed) with new trailer and sails. Obviously this depends on local area prices for plywood and on how much you choose to customize your boat with costly finishes, extensive fiberglassing etc But you'll end up with a boat that provides results comparable to an $8,000 - $10,000 craft And over the building period the money is paid out in manageable increments, not in one big chunk.

With my Pacific Pelican I have found there's always more to learn about dinghy cruising. With this reliable, safe, yet lively, craft that also serves as my home away from home, my confidence increases with each new cruising experience and I look forward to ever more ambitious destinations in the seasons ahead

MATERIALS LIST

MARINE PLYWOOD 4' X 8' SHEETS

Sheet A: 3/4" ply. - Bow and Stern Transoms, Centerboard, Rudder, Rudder core, Tiller cheeks.

Sheet B: 1/2" ply. - Centerboard trunk, Thwart, Rudder cheeks, Floor timbers.

Sheet C: 1/2" ply. - Keelson, Thwart, Footlings, Floor timbers.

Sheet D: 3/8" pIy. - Aft Side planking

Sheets E and F: 3/8" ply. - Forward side Planking, side deck, bowsprit.

Sheet G: 3/8" ply. - Forward bottom planking.

Sheet H: 3/8" ply. - Foredeck, Cockpit seats.

Sheet I: 3/8" ply. - After Deck, After Coaming, Butt plates, Cockpit seals.

Sheet J: 3/8" ply. - Aft bottom planking, Deck knees, scrap for gussets.

Sheet K: 3/8" ply. - Fore and Side Coaming, Deck knees.

Sheet L: 1/2" ply. - Deck beams, Headledges, Footlings, Chain plate backing.

In total, one 3/4" sheet, three 1/2" sheets, and eight 3/8" sheets are required. If the side planking and decks are made from 1/4" plywood, five of the eight 3/8" sheets can be 1/4". They are sheets D,E,F,H, and I. We recommend staying with 3/8" ply however, for all - around sturdiness. If panel I is 1/4", the aft coaming will not be sturdy enough as it is laid out. Another partial panel of 3/8" or 1/2" plywood will be required. Also, the material for the aft cockpit seats will be marginal since it comes from panels H and I.

CLEAR STRAIGHT GRAIN FIR BOARDS

(All widths and thicknesses are nominal unless identified as true).

- 2" X 6"

- 6' long for the bow transom top and bottom cheek pieces. This should be planed down to a true 1" thickness.

- 2" x 4"

- two pieces each 8' long for the remaining transom cheek pieces. Also planed down to a true 1".

- 1" x 8"

- two pieces 16' long. These are for the laminated chine and sheer clamp. The sheer clamp strips should be cut off the boards first and then the boards should be planed down to a true 1/2" for the chine

laminates. - five pieces 8' long. For the transom knees, thwart stringers and stiffeners, the bowsprit, frame battens and stempost.

- two pieces 16' long. These are for the laminated chine and sheer clamp. The sheer clamp strips should be cut off the boards first and then the boards should be planed down to a true 1/2" for the chine

- 1" x 6"

- three pieces 6' long. For the bedlogs and the stanchions.

- 1" x 4"

- three pieces 8' long. For the side deck strangers, mast and deck carlngs.

(You may wish to figure out how you will lay out the parts on these boards before you start to cut them. Remember to select the direction of end grain for maximum resistance to splitting).

MAHOGANY

A 1/2" by 6" (true) by 14' long board could be used as the top layer of the keelson. This will dress up the interior of the boat. It will have to be planed to size at the yard. You will also need some mahogany for

coaming trim.

SPARS, TILLER

Specific lumber requirements are not given for these parts because there is some choice in how they are made. The spars could be laminated from some combination of fir or spruce, and mahogany, for example, or you may choose to purchase your spars. The tiller could be likewise laminated of several woods.

LOA (without bowsprit) = 14' 7"

FloorLength = 13' 1"

Beam = 6' 7"

Draft (board up loaded) = 5"

Draft (board full down) = 3' 8"

Weight (all up/all 3/8" glassed) = 600#

Weight (¼" decks 7 sides glassed) = 540#

Sail Area (main) = 105sf

Sail Area (jib) = 40sf

Freeboard (above waterline) = 24"

Cockpit Length = 8' 0"

Capacity 4 adults/motor/gas/gear = 1,000#