This manual covers the construction of boats using modern ply on frame techniques - the stitch and tape method of construction is fine for boats below 18' or so although I have used it for larger craft, but in larger boats it gets expensive and is not necessarily the easiest method to use. So, for boats over 16 or 18' I tend to use a combination of methods, often based upon a basic framework of slotted ply components - ply frames/bulkheads and fore and aft girders (egg-box construction) and use epoxy only where it is appropriate and cost effective.

This book describes the construction of larger yachts and motor craft (above 18') using various different types of framework and planking processes from the pure stitch and tape, through clinker to hard/multi-chined and of course, ply on frame construction.

Several of the methods described can be used for all sizes of craft where the builder does not want to use epoxy.

The construction of decks and cabin tops/superstructures is also described using various methods - plywood, strip plank, vertical staving etc and the manual concludes with the various ways in which you can finish your boat - these chapters are also relevant to other forms of hull construction - strip planking, cold moulded etc.

Note - The Manual of Fit-Out for Yachts and Launches will be an excellent companion to this manual and will help you complete your boat.

Sample Pages

Introduction

Chapter 1

Frameworks

1.1 Traditional Frameworks for Ply Over Frame Construction

1.2 Modern Frameworks for Ply Over Frame Construction

1.3 Epoxy Fillets vs Wood Filleting for Joining Plywood Components

1.4 Notes on Using Epoxies for Bonding Wood Components

1.5 The Choice of Design

Chapter 2

The Work Area

2.1 General Comments

2.2 The Size of the Workshop

2.3 The Tools You Will Need

2.4 Basic Marking Out

Chapter 3

Common Wood Joints

3.1 Solid Wood Joints for Frame Construction

3.1.1 Typical Joints for Solid Wood

3.1.2 The Scarf Join

3.1.3 Solid Wood Joints for Chines

3.2 Epoxy Joints for Frame Construction

3.2.1 Replacing Wood Fillets with Epoxy

3.2.2. Replacing Wood with Epoxy Joints between the Plywood Frames/Bulkheads and Hull Skin

3.2.3 Epoxy Joints for Chine Seams

3.2.3.1 The Simple Epoxy/Glass Chine Join

3.2.3.2 The Combi Epoxy/Wood Chine Join

3.2.3.3 The Edge Girder Chine Method

Chapter 4

Materials

4.1 Solid Wood for Frameworks

4.2 Plywood for Frameworks

4.2.1 Can I use cheaper exterior plywood for the frames and bulkheads?

4.2.2. If I sheath the boat can I use exterior plywood for the hull planks/panels?

4.3 Glues & Adhesives

4.4 Fastenings

4.4.1 Screws

4.4.2 Gripfast Nails

4.4.3 Other Marine Fastenings

Chapter 5

Setting Up the Framework

Chapter 6

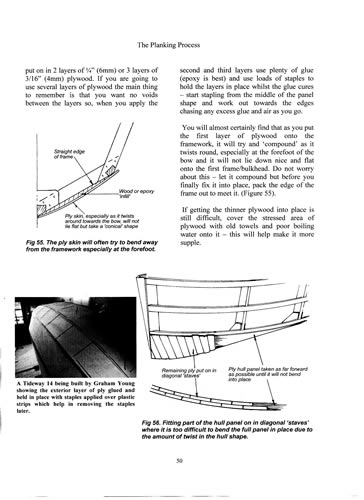

The Planking Process

6.1 Preparing the Framework for Planking

6.2 Planking the Hull (General Notes)

6.2.1 Multi-layered Plywood Planking

6.2.2 Joining Plywood Plank Lengths

6.2.2.1 Butt Joins

6.2.2.2 Scarf Joins

6.2.3 Planking for Stitch and Tape Hulls

6.2.4 For Plywood Plank over Frame Hulls

6.3 Finishing a Plywood Hull

6.3.1 Painting Only

6.3.2 Sheathing

6.4 Clinker or Lapstrake Planking

Chapter 7

The Hull Exterior

7.1 Fitting Gunwales, Rubbers etc

7.2 Skeg, Deadwood and Wood Keels

7.2.1 Fitting Skegs/Deadwood

7.2.2 The Outer Stem

7.2.3 Bilge Runners

7.3 Marking the Water Line

7.4 Turning the Hull Over

Chapter 8

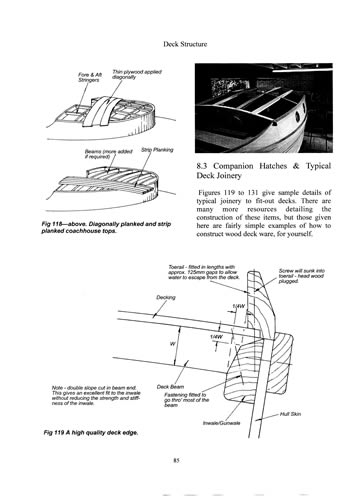

Deck Superstructure

8.1 Decking

8.1.1 The Deck Structure

8.1.2 The Cockpit

8.1.3 The Deck

8.1.3.1 Sheathed Deck Covering

8.1.3.2 Teak Deck Covering

8.2 Coachhouses, Cabin Tops and Superstructures

8.3 Companion Hatches and Typical Deck Joinery

Chapter 9

Painting & Finishing