has 129 diagrams helping to explain the process

Many Selway Fisher designs can be built using the clinker ply method and some have been specifically designed for this method - this manual has 129 diagrams helping to explain the process from the set-up of the building jig, through making the internal framework, spiling the plank shapes and fitting them and finally fitting out the hull, fitting the deck structure etc and finishing the boat and shaping and making masts and spars.

To start the book, modern clinker construction is compared with more traditional methods making this book applicable to those wanting to use modern epoxies and plywood to build a clinker boat as well as those who want to stick strictly to traditional techniques. Rather than just concentrating on one particular modern method, this book looks at several variants of the modern methods first, including the ribband-less, stringered and what some call the Herreshoff method plus methods for flat bottomed craft and those using purely rounded moulds (from older designs), giving the reader a wide choice of methods to use and combine.

If you are thinking of using the Clinker Plywood method, read this manual first.

Sample Pages

Contents

Chapter 1

Traditional vs Modern Methods of Clinker Construction

1.1 General Notes.

1.2 Traditional Clinker Construction.

1.3 The Modern method of Clinker/Ply Construction

Chapter 2

Tools, Skills & the Workshop

2.1 Tools

2.2 Skills

2.3 The Workshop

Chapter 3

Materials for Clinker Ply Construction

3.1 General

3.2 Suitable Wood Materials

3.3 Suitable Fastenings

3.4 Glues

Chapter 4

A General Discussion of Modern Clinker/Ply Methods

4.1 General

4.2 Ribband-less Building Jig Method

4.3 The Ribband Building Jig Method

4.4 The Stringer Building Jig Method

4.5 Rounded Moulds with Ribbands or Stringers

4.5.1 Lining Off

4.6 The No-Gains in Planking Method

4.7 Clinker with Flat Bottomed Craft

4.8 The Herreshoff Method

4.9 Pre-Shaped Planks

4.10 Over View and Converting Traditional to Modern Clinker Construction

Chapter 5

The Building Jig

5.1 General Notes

5.2 The Building Jig

5.3 The Strong Back

5.4 The Moulds

5.5 Setting Up the Moulds

Chapter 6

The Internal Hull Structure

6.1 General Notes

6.2 Inner Stem Post

6.3 The Transom

6.4 Hog (internal Keel)

6.5 Floors and Frames

6.6 Inwales (gunwales)

6.7 Stringers

Chapter 7

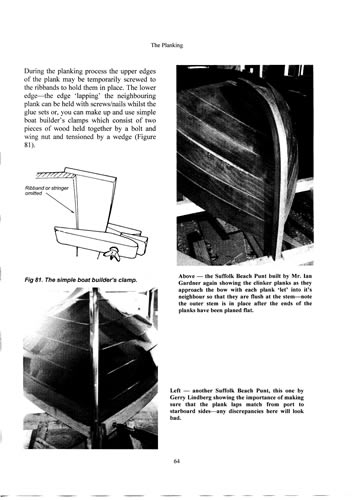

The Planking

7.1 General Notes

7.2 The Ribbands/Stringers

7.3 Preparing the Jig and Framework for Planking

7.4 ‘Spiling’ the Shape of the Planks

7.4.1 The First (Garboard) Plank

7.4.2 ‘Hemming’ the Remaining Planks

7.5 Joining Plywood Plank Lengths Together

7.5.1 Butt Joins

7.5.2 Scarf Joins

7.5.3 Saw Tooth or Castelated Joins

7.6 ‘Let’/’Gains’ at the Ends of the Planks

Chapter 8

Fitting Out the Hull

8.1 The Next Stage

8.2 External Parts of the Hull

8.2.1 External Stem & Skeg

8.2.2 Levelling the Hull

8.3 The Gunwales

8.3.1 The Inwales

8.3.2 The Quarter Knees & Breasthook

8.4 The Seating (thwarts)

8.4.1 Thwart (seat) Risers

8.4.2 The Thwarts

8.4.3 Thwart Knees

8.4.4 Thwart Stanchions

8.5 Centreboards/Daggerboards

8.5.1 The Case

8.5.2 The Centre/Daggerboard

8.5.3 Fitting Pivots

8.6 The Decking

8.6.1 The Deck Structure

8.6.2 The Deck

8.6.2.1 Sheathed Deck Covering

8.6.2.2 Teak Deck Covering

8.6.3 Coamings

Chapter 9

Masts and Spars

9.1 General Notes

9.2 Materials for Wood Masts & Spars

9.3 Solid Masts & Spars

9.4 Hollow Masts & Spars

9.4.1 Round Section Hollow Masts & Spars

9.4.2 Rectangular Section Hollow Masts & Spars

Chapter 10

Painting and Finishing

Chapter 11

Clinker Plywood Designs

11.1 General