Note:Tom Hruby has written an excellent addendum to these plans. Anyone building or considering building a Flapdoodle should read it. Click HERE

About Flapdoodle plans:

New... a high quality DIY folding sail dinghy. What's more, you can build it your way. Bill Weller has produced plans in easy to navigate HTML format that give step-by-step instructions plus customizing options along the way. There are over twenty pages of instructions and dozens of photographs and diagrams to help even a novice builder.

Mr Weller started this project about six years ago and and finally has plans ready to sell. The availability of PVC laminated cloth was key to making it work. The name Flapdoodle Dinghy was given to it by his 80 year old mother.

The dinghy is mostly composed of hardwood plywood, but has some hardwood pieces. It folds down flat about the size of a surfboard and the main body can be carried under one arm. Open, it becomes a rigid 7'10" x 4 foot beam dinghy of classic proportions. It could be built for about $300; much less if desired by using the construction options.

Mechanics of the Flapdoodle Design

The classic dinghy shape dates back to the 1800's as a tried and proven design and is responsible for the Flapdoodle's ability to glide through the water with hardly a ripple, even when heavily loaded.

First, the curves of the panels not only define this shape, but give it the necessary rigidity.

Secondly, shear forces were employed where possible instead of putting the materials in compression, or tension.

Forces in Shear

The PVC cloth used to make the waterproof panel hinges is laminated to Dacron. When it is glued to the hull panels and the covers glued on, #4 x 3/8" screws hold everything firmly. When the boat is loaded, shear force (mostly) tries to pull the cloth laminates sideways, out from under the layers of glue and wood. It takes considerable force to do this.

Naturally...

The entire dinghy design is a result of natural curves. The red curve below defines the keel, and the black curve makes the gracefull hull shape. Both curves are designed to follow the natural bend of the wood just as classic dinghy did a century ago; a tried and proven shape.

As a result of this, any two of the spreading components below will produce the final shape:

(not to scale)

There is no need for hinges to force the seat or transom to open the boat. During assembly the center seat will spread the sides with only moderate force by you. The transom and bow plate drop into place smoothly.

Surprisingly, trying to spread the sides further will force the ends together. Included as side forces are the mast and daggerboard.

A load on the bottom of the boat (including the seat which is supported via a pedestal to the keel) forces the sides in this direction:

Locking up

The transom tries to move in the directions indicated below. In addition, a trolling motor or small outboard causes considerable force (right).

It was a challenge to find a way to handle these forces and keep the weight and complexity of design within reason, but locking T slots provided a solution. As a result, the transom slides smoothly into place during assembly.

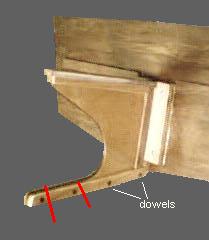

The peculiar inner curve of the stern lock post was dictated by accessibility to the large brass screws (red) that attach it to the keel and skeg (not shown). More screws are used on the bottom. The transom has a "T" slot that slips onto a mating "T" on the post.At the top is a similar T that mates with the rear seat, locking the entire stern into a rigid unit.

The foredeck uses a similar locking arrangement.

FAQs - Answers by Bill Weller

Q: Obviously, there is a waterproof fabric at the joints. Is it exposed on the bottom where it could become damaged in beaching the boat or is it somewhat protected by what appears to be a centerline keel plan?

A: Obviously, metal would be the best choice for "beach scooching" as my family calls it, since it is a highly abrasive operation.. I kept this in mind when I designed the Flapdoodle. The waterproof part of the seam is under a layer of Dacron laminated to it with Acrylic latex caulk and I recommend a finish coat of varnish. The seam for the most part resides in a groove for protection. You will laugh at this one.... I roll my own cigarettes and the rolling machine material does not last very long. I made a replacement out of scrap fabric from the Flapdoodle. After several months, it shows no wear even under high magnification, and is still flexible.. Outlasted 3 or 4 rolling machines and looks like it did at the beginning.

Q: Would luan plywood work (the kind you can get at Home Depot or Lowe's) for construction or would one need to use marine plywood?

A: I was half through the second Flapdoodle design when I found a sheet of luan at Home Depot that is the best piece of plywood I have ever found of any species. I keep looking to see if they got more. Another sheet later from HD sucked so bad it was not usable for anything structural, yet had a sticker from the same manufacturer. The veneer was about 1/3 the thickness of the good sheet. Look for a thick layer of the final outside veneer with the least fancy grain. IE, plain looking. Also, the good sheet tested 20% lighter! I vowed it would be the material of choice for the Flapdoodle III if my health will allow a third version.

Q: Assuming that I opted to leave out the daggerboard trunk, what would the Flapdoole weigh?

A: It is not possible to give a weight (plywood varies + or - 20% regardless of strength), but I can carry the folded part under one arm with all the options such as daggerboard box, but figure about 45# for the folded part.

Q: In your opinion, could it be assembled and launched from the cockpit of a sailboat?

A: I have no idea yet, but it is easy to assemble (more so than the Seahopper type). My guess would be if you can launch any other type of dinghy, you can launch a Flapdoodle. Incidentally, the Flapdoodle assembles without any tools.

Q: Can a leeboard be rigged instead in order to save weight?

A: Leaving the DB box out will save a lot in weight and ease of building. I plan to add a leeboard design later to the plans. But since this is a real dinghy when assembled, there is no reason any dinghy style leeboard would not work. There is an excellent essay by Jim Michalak here. Other weight saving suggestion are given as you go through the plans.

Q: What is the folded length of the boat? Is it still 7' 11" or is it longer?

A: The Flapdoodle is longer when closed... about 8' 3". This is due to the geometry changes between the open and closed positions. If you lower the height of the foredeck and stem (not the height of the boat) the overall closed length is reduced. Since much of the fore part is out of the water in use, you could start building the FD and when you get to the section where the front plate is installed, cut off say, 6". The bowplate would have to be wider of course, and so would the PVC front panel. Again, I had thought of all this during design, but keep in mind where the mast step, etc. would be if you did this. Also, the skeg could be shortened if you do not intend a rudder.

Q: Can I add to the length of the Flapdoodle by splicing two feet (or more) onto a eight foot panel cut from a 4 x 8 sheet of plywood?

A: I do not know for sure, but I have serious doubts. I fear it would make hinging the panels a nightmare. The geometry of the Flapdoodle was painstakingly worked out. Changing the length at random would most certainly change everything else, including strength of the dinghy.

FEEDBACK

Hi Josh,