Six years ago, we bought a house in Greece. It had been used as a holiday home and the only heating in the house was by an open fireplace.

Now, winters in Greece can be cold. Where we are, the northern winds come from the Balkans and we've had snow every year since we moved here. Winter temparatures regularly fall to below 40F (5C).

Our main living area is a large open plan, part 2 storey space, 30' x 20' x 23' high (9m x 6m, x 7m high), the walls are 10" (25cm) clay block, rendered on both sides, the floor is timber boards over concrete and the tiled roof has just 1" (2.5cm) of insulation - so we don't live in a well insulated house either!

During that first winter we suffered! Evenings were spent huddled around the fireplace, the inside temperature rarely rose above 55F (13C).

I had to do something!

I'd been told that woodstoves were more efficient than open fireplaces, so my first idea was to put a steel front on the open fireplace, with a glazed door. My reasoning was that this would essentially be a stove - with brick side walls - the heat from the fire would warm the walls which in turn would warm the room.

It made no difference at all!

This got me thinking that, for a stove to work efficiently, is should not be lined with

firebricks (which are simply a scaled down version of the brick side walls described above), instead, the stove should be designed so that the steel surrounding the fire takes the heat from the fire and dissipates it into the surrounding space as quickly as possible.

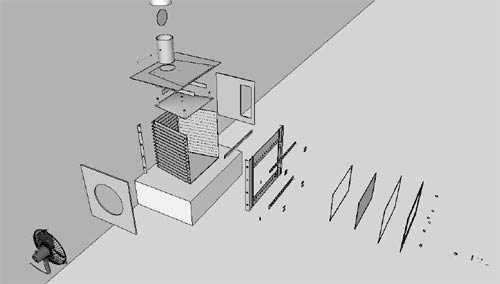

I designed such a stove, it has steel fins around the firebox, no firebricks, and a large fan - which is a modified pedestal fan.

Having designed it, I took the drawings to my local blacksmith and he made it for me. It works! From a cold start, the fire usually takes 30 minutes for the logs to be burning well. At that stage we put the fan on high and the whole living space heats up by 10 degrees within 15 minutes. After another 30 minutes or so, the room temperature is up to 70F (21C). We then turn the fan onto a low setting.

Another benefit is that, by force-circulating the air with a fan, there is very little stratification (the difference in temperature between ground floor level and first floor ceiling).

And another important benefit is that of efficiency - we burn the same amount of wood here as several of our neighbours who live in much smaller houses.

The stove that is the subject matter of these plans is based on the above design, with a few improvements - the depth of the firebox has been increased so that ash doesn't need to be removed so often, reinforcing for the top is now hidden below rather than on top I've included ventilation above the door to create a glass cleaning airwash and the complete unit is narrower, yet retains the original firebox size.

Building the stove should be within the skills of the average diy-er. Welding skills will be needed and it would be worth considering having the steel cut to size by the supplier.

Note that my stove was made in Greece using 5mm steel plate. Here I have generally specified 1/4" (6mm) steel plate, which should be more durable.

Plans consist of 50 pages of drawings, photos, diagrams and instructions.