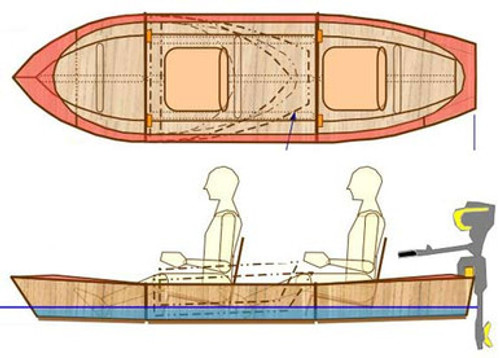

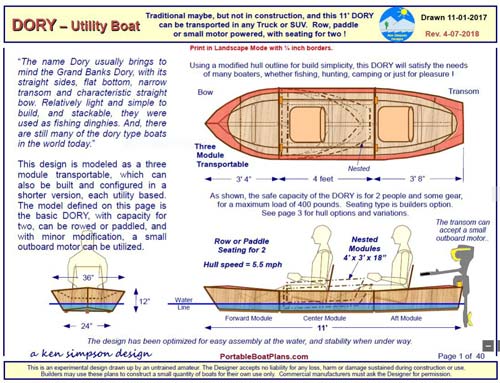

One of my favorite all time hull shapes is the Grand Banks Dory. It had a flat bottom, generous sloped sides, and an ample length to width ratio, with good cargo capacity, and was relatively easy to construct. After many years of designing, and building, small portable boats of unique but rather rectangular shape, I decided to delve into a miniature GB Dory hull design. The end result is an 11 foot long, 3 foot wide, 3 module hull, capable of a 400 pound load, and aptly named The DORY.

After I completed the basic drawings and assembly instructions, prototype construction was to be the next design phase. Unfortunately, a medical condition prevented me from doing so. As a result, I posted the concept on the website as a new plan, without a build, just to see what the reaction would be. Sure enough, I had potential builders contact me. The rest of this story is about the detailed construction of The DORY prototype, by Quincy Maxwell of Temora, Australia.

We had never conversed before, and I am sure there was trepidation on both our parts regarding the new build. That was short lived, however, as the first questions, and photos, proved that The Dory was in very good hands. Quincy has a long history of boat construction, and woodworking projects,

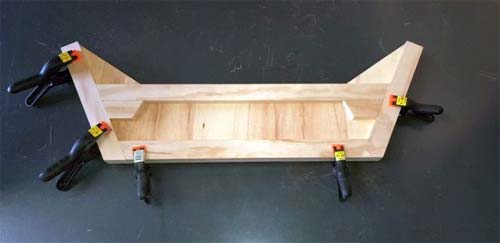

so tools and materials were not to be an issue. In only a few short days, he had plywood purchased, panels cut and construction started. Oh yes, he also had to convert the dimensions to metric in the process. The first photo, next page, is of the initial bulkhead assembly, of which there are four, and all are identical. They must be kept flat during assembly, to minimize hull warp.

Initial Bulkhead Assembly

Note that all 1x2 edge supports are glued and clamped to the plywood bulkhead. Screwing them in place is a builders option. Further refinement of the bulkhead assemblies is to round all internel edges, 1/2" radius, to make them more friendly to the touch.

Basic Module Construction

Now things are starting to take shape. The 4 foot long center module is about as simple as it gets, a rectangular assembly, as shown above. The critical aspect here is to keep the assembly flat, and the shape true. Allow the assembly to cure while on a flat surface, and make sure the module diagonal measurements are near identical. This method is detailed on the plans.

Basic Module Construction

Insuring that the base is well bonded to the hull chine edges is most important, and Quincy has developed a method of sanding smooth and level those edges. A 3 foot 2 x 3 with course sandpaper stapled to one end levels each side, as shown below. Perfect!

The end result is shown below. The base panel fits nice and flat, and the assembly is rigid. To make sure of this, he has added temporary weights on each bulkhead to hold the assembly flat to the floor while curing. Note also the added inside chine supports on the inside edges, for additional security.

These assembly steps would be repeated for all three modules, with some minor modifications. The picture on the next page demonstrates the relavent hull shape, after the forward and rear modules were semi-finished. The base panel on each end module rises slightly , requiring additional clamping.

Basic Hull Configuration

Above and below are good views of the overall hull configuration, 3 modules with deeply slanted sides, good length to width proportions, providing the stability that the GB DORY was famous for.

The hull nearly complete. Final sanding and waterproofing are the next challenges. To say the assembly went without any hiccups would be a false statement. The original base thickness was specified as 1/2" plywood, but bending it to conform to the upswept bow was almost impossible, and with Quincy's recommendation, all base panels were then changed to 3/8" thickness. Later water tests would prove this to be most acceptable, as he intentionally overloaded the hull without any degredation of the seals or materials.

Hull Features

Certain specified materials, like the Ultra-Thin Fiberglass Tape, are not available the world around. It was Quincy's challange to find equivalent materials in his country of Australia. I am sure others may have this same problem. But please note, the basic design is flexible enough to withstand the use of other materials and processes without assembly complication.

It's also very important to show why this is a portable boat. All 3 modules nest to form a travel package only 4' long, 3' wide and 18" high. Small enough to fit in most small SUV's and all trucks and motor homes. Yes, you can take it with you, without car-topping.

Of course, the final result is what interests us the most, in the water pictures. The following are of the initial test outings, and Quincy did a great job of that as well. At first it was he and his dog "Rivet" in the above picture. Other test would include family members and friends.

In Water Pictures

Here, Mrs. Maxwell is going along for a casual ride, with Rivet on her lap.

And finally, a good friend joined in the testing phase, to determine the load capability of The DORY.

Needless to say, The DORY met the design criteria quite well. Quincy reports that the hull is quite stable, and shifting weight from side to side does not disrupt it's handling, nor did it take on any water. There was an observation that when a single occupant is aboard, the aft of the craft sits a little low in the water, with the bow lifted. To minimize this condition, the transom drawings have been modified to provide additional buoyancy aft, creating a more level gunwale in all load conditions.

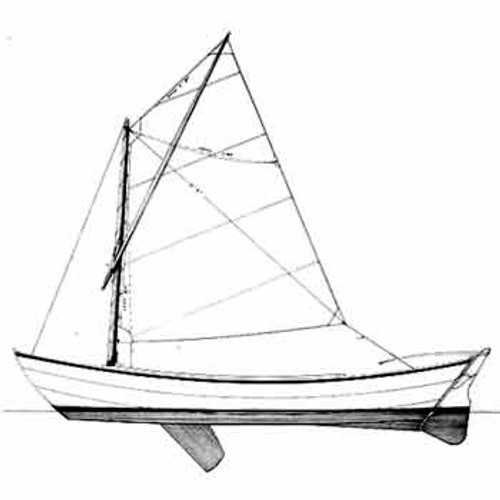

And it's important to mention that The DORY can also become a vey capable single occupant SKIFF. Just eliminate the center module, and the Skiff version is born. No additional components required. The following two pictures illustrate that quite well.

Note too that a 30 pound thrust trolling motor has been employed. It travels well with the motor, but the Maxwell family enjoy paddling the Skiff just as much. However, Quincy wishes he had a larger trolling motor for the 3 module DORY hull, as the 30 pounder weighs almost as much as a 40 pound thrust motor which would provide better performance under load.

Overall, the Dory performed without any major difficulties. More buoyancy in the aft, as previously mentioned, will certainly improve capacity. The real test here was for Quincy, to construct a prototype boat in record time, for which I am very grateful. The end result is more than I expected, and The DORY, as proven by Quincy, will be a wonderful addition to my Portable Boat Plans portfolio.

Thank you again Quincy, and the entire Maxwell family.

Ken Simpson